arrow_back_ios

Main Menu

arrow_back_ios

Main Menu

- Accessories

- Actuators

- Combustion Engines

- Durability

- eDrive

- Mobile Systems

- Production Testing Sensors

- Transmission Gearboxes

- Turbo Charger

- DAQ systems

- High precision and calibration systems

- Industrial electronics

- Power Analyser

- S&V Handheld devices

- S&V Signal conditioner

- testing

- HATS (Head and torso simulator)

- Artificial Ear

- Electroacoustic hardware

- Bone conduction

- Electroacoustic software

- Accessories for electroacoustic application

- Pinnae

- Accessories for electroacoustic application

- DAQ

- Drivers API

- nCode - Durability and Fatigue Analysis

- ReliaSoft - Reliability Analysis and Management

- Test Data Management

- Utility

- Vibration Control

- Acoustic

- Current / voltage

- Displacement

- Force sensors

- Load cells

- Multi Component Sensors

- Pressure

- Strain Gauges

- Strain Sensors

- Temperature Sensors

- Tilt Sensors

- Torque

- Vibration

- Temperature

- LDS Shaker Systems

- Power Amplifiers

- Vibration Controllers

- Measurement Exciters

- Modal Exciters

- Accessories for modal exciters

- Artificial Ear

- Artificial Mouth

- Bone Conduction

- Data Acquisition

- HATS Head Torso Simulator

- Microphone

- Signal Conditioning

- Test Solutions

- Accessories Electroacoustic Application

arrow_back_ios

Main Menu

- Bridge calibration units

- Microphone calibration system

- Sound level meter calibration system

- Strain Gauge precision instrument

- Vibration transducer calibration system

- Accessories for high precision and calibration systems

- Multi channel amplifier

- Single channel amplifier and amplifier with display

- Weighing indicators

- Weighing electronics

- Accessories for industrial electronics

- Piezoelectric

- Weighing electronics

- Press fit controller

- Weighing indicators

- CCLD (IEPE) signal conditioner

- Charge signal conditioner

- Microphone signal conditioner

- NEXUS

- Accessories for signal conditioner

- BK Connect / PULSE

- catman Enterprise

- catmanEasy AP

- Software Downloads for Perception / Genesis HighSpeed

- Tescia

- Test for I-deas

- ReliaSoft BlockSim

- ReliaSoft Cloud

- ReliaSoft Lambda Predict

- ReliaSoft Product Suites

- ReliaSoft RCM++

- ReliaSoft XFMEA

- ReliaSoft XFRACAS

- ReliaSoft Weibull++

- Classical Shock

- Random

- Random-On-Random

- Shock Response Spectrum Synthesis

- Sine-On-Random

- Time Waveform Replication

- Vibration Control Software

- Microphone sets

- Microphone Cartridges

- Acoustic calibrators

- Hydrophones

- Special microphones

- Microphone Pre-amplifiers

- Sound Sources

- Accessories for acoustic transducers

- Test automatic

- Fiber Optic Technology

- Inductive technology

- Strain gauge technology

- Accessories for displacement sensors

- Bending / beam

- Canister

- Compression

- Single Point

- Tension

- Weighing modules

- Accessories for load cells

- Experimental testing

- Fiber Optic Technology

- Transducer Manufacturing (OEM)

- Accessories for strain gauges

- CCLD (IEPE) accelerometer

- Charge accelerometer

- Fiber Optic Accelerometer

- Force transducers

- Reference accelerometer

- Impulse hammers / impedance heads

- Tachometer probes

- Vibration calibrators

- Cables

- Accessories for vibration transducers

- Accessories

- High-Force LDS Shakers

- Medium-Force LDS Shakers

- Low-Force LDS Shakers

- Permanent Magnet Shakers

- Shaker Equipment / Slip Tables

- Fatigue and Durability Analysis Training

- Reliability Training Courses

- Sound and Vibration Courses

- HBM Courses

- Delete content

- Request Calibration

- Calibration Services for Transducers

- Calibration Services for Handheld Instruments

- Calibration Services for Instruments & DAQ

- Resources

- Electroacoustics

- Environmental Noise

- Noise Source Identification

- Product Noise

- Ramp Noise Testing

- Static Engine Noise Certification

- Sound Power and Sound Pressure

- Flight Certification

- Acoustic material testing

- Vehicle Pass-by Noise

- Production Testing and Quality Assurance

- Machine Analysis and Diagnostics

- Structural Health Monitoring

- OEM Sensors for the Agriculture Industry

- OEM Sensors for Robotics and Torque Applications

- OEM Sensors Medical

arrow_back_ios

Main Menu

- Housing

- Communication processor

- Amplifier modules

- Connection boards

- Special function modules

- Accessories for MGCplus

- Binaural Audio

- Outdoor microphones

- Probe Microphones

- Sound intensity probes

- Surface microphone

- Array microphones

- Other special microphones

- Production line test

- Microphone Cables

- Tripods

- Microphone booms

- Microphone adapters

- Electrostatic actuators

- Microphone windscreen

- Nose cones

- Microphone holders

- Tripods

- Other accessories for acoustic transducers

- Microphones outdoor protection

- Adhesives

- Protective coatings

- Cleaning material

- SG Kits

- Solder terminals

- Other strain gauge accessories

- Cables

- ZeroPoint Balancing

- TCS Balancing

- TC0 Balancing

- Magnets

- Mounting clips/bases

- Studs, screws and washers

- Adhesives/Tools

- Adapters

- Mechanical filters

- Other accessories

- Calibration of Microphone and Preamplifier

- Calibration of Accelerometers

- Pressure Calibration

- Displacement

- Calibration of Sound Level Meters

- Calibration of Sound Calibrator and Pistonphone

- Vibration Meter

- Vibration Calibrator

- Noise Dosimeter Calibration

- Telephone Headset And Handset Testing

- Testing Of Hands-Free Devices

- Headphone Testing

- Hearing Aid Testing

- Speaker Testing

- Smart Speaker Testing

- Acoustic Holography

- Underwater Acoustic Ranging

- Wind Tunnel Acoustic Testing – Aerospace

- Wind Tunnel Testing For Cars

- Beamforming

- Questions

- Flyover Noise Source Identification

- Real-Time Noise Source Identification With Acoustic Camera

- Sound Intensity Mapping

- Spherical Beamforming

- Order Analysis

- Machine Diagnostics

- Health and Usage Monitoring Systems (HUMS)

- Gas Turbine Testing

- Questions for Machine Analysis

- Tunnel monitoring with Fiber Bragg sensors

- Monitoring Solutions for Civil Infrastructures

- Monitoring Solutions for Wind Turbines

- Monitoring Solutions for the Oil and Gas Industry

- Monitoring Solutions for Railways

- Monitoring Solutions for Civil Engineering

- Available Monitoring Services

- Foundation Monitoring Using Strain Gauges

- Switchgear Tests

- Transformer Equivalent Circuit Diagram | HBM

- Current Zero Testing

- Testing High Power Circuit Breakers Safely

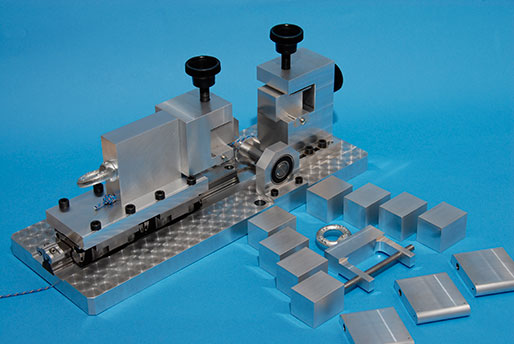

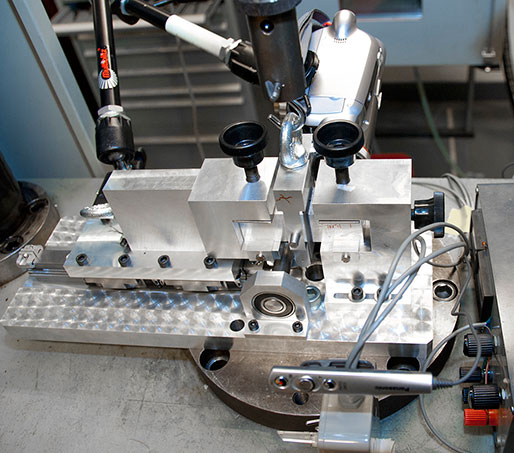

Force transducers from HBM

The research on friction between steel cables and rubber was part of a PhD thesis study by Arjo Loeve, who is now a post-doctoral researcher. This study was geared towards the development of new technology for form guidance of scopes, to be used for medical examinations in the human body. During insertion of flexible endoscopes, undesired bends sometimes occur in the endoscope hose, which may cause issues such as painful stretching in the patient's intestine. This may even give rise to adverse complications, such as perforation of the intestine during a colonoscopy. Some manufacturers have actually introduced technologies for form guidance onto the market, but their functioning is not yet optimal and they are extremely expensive. Most endoscopes do not use form guidance yet, and only offer limited options to fix the shape of the hose.

Force transducers from HBM

The research on friction between steel cables and rubber was part of a PhD thesis study by Arjo Loeve, who is now a post-doctoral researcher. This study was geared towards the development of new technology for form guidance of scopes, to be used for medical examinations in the human body. During insertion of flexible endoscopes, undesired bends sometimes occur in the endoscope hose, which may cause issues such as painful stretching in the patient's intestine. This may even give rise to adverse complications, such as perforation of the intestine during a colonoscopy. Some manufacturers have actually introduced technologies for form guidance onto the market, but their functioning is not yet optimal and they are extremely expensive. Most endoscopes do not use form guidance yet, and only offer limited options to fix the shape of the hose.